Create a home both separate from and intertwined with nature.

Gregory Wiedemann, architect

Check out the previous chapters of the Cabbage Dispatch (and more) here.

I was nine years old when my dad, an architect, designed a substantial addition for the 19th-century farmhouse I grew up in. We continued to live in the house through the years of construction, even when it came time to demo the kitchen. The fridge, oven, and a makeshift sink were moved into the dining room and spread out around the perimeter of the room, leaving just enough space to squeeze behind someone sitting at the oversized heirloom dining table. We lived like that for a year, eating at our fancy table in very unfancy surroundings.

One night, after the builders went home, my dad invited my older sister and me to peek at the construction site attached to our house. He opened the makeshift door that separated our current home from the new home, exposing a maze of 2×4 stud walls and fresh plywood subfloors. Suddenly, a home — a structure, a building — became something malleable, manmade, and moveable. Rooms were designed and created. I had only ever lived in spaces that were established before me. This blank slate was exciting.

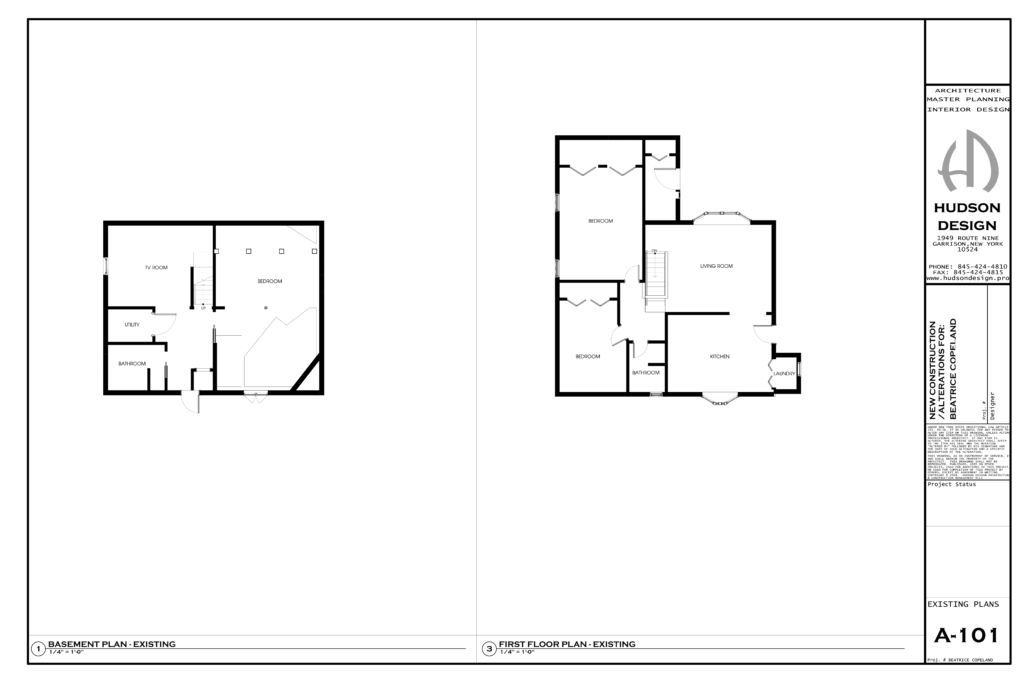

I felt that same excitement when I got the floorplans of my home. At under 1,500 square feet, with two beds and two baths, the footprint was an ideal size, however there were a few pain points that needed attention. There was no designated dining area, the main bathroom was tiny (see: three foot tub), the path to the bedrooms cut awkwardly across the living room to a corridor of wasted space, and in the basement a 12′x12′ slab of bedrock protruded into the room, taking up valuable real estate. Overall, the house felt disconnected from its natural surroundings. So with the plans in front of me, and my dad’s experience to guide me, we sketched out solutions.

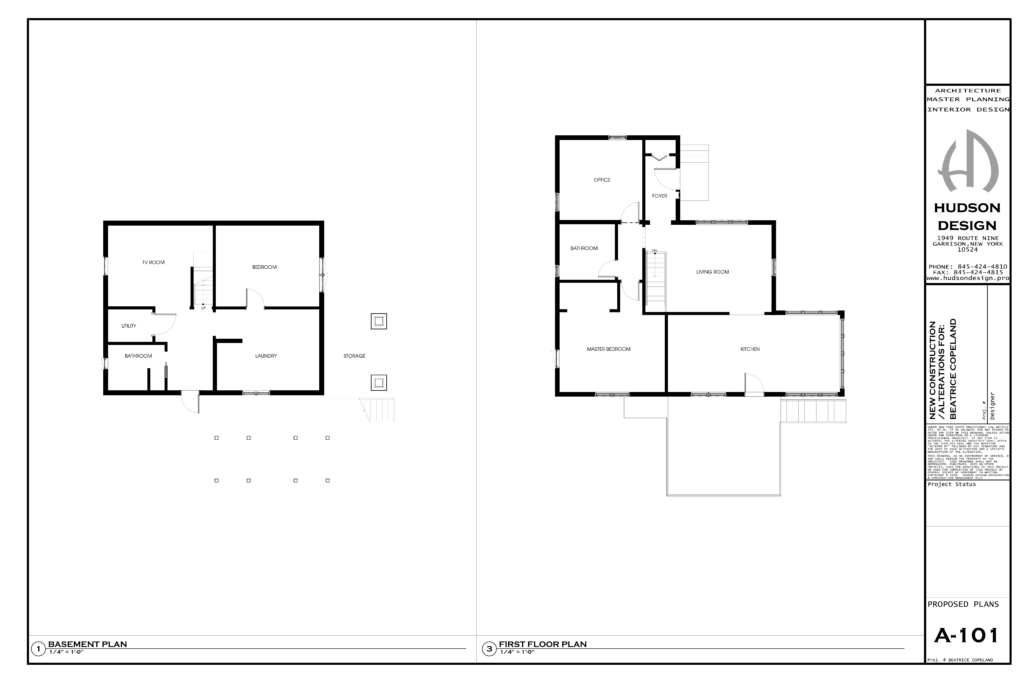

Staying eco- and budget-friendly at this stage meant making a few strategic changes. I opened the wall at the top of the stairs, creating a hallway that rerouted the flow, and divided the remaining square footage more equitably into a primary bedroom, bathroom, and office. After lots of brainstorming, I used expanding cement to break up the basement slab. The biggest change was a 9′x11′ addition to the footprint of the house. On the ground floor, it would be a garden shed, and above, a much-needed dining area surrounded by windows.

With the new walls framed, the electricians and plumbers got to work. It was July and nearing the deadline to order windows so that they would arrive in time to seal the house before winter. When it comes to buying new windows, there’s a lot of variety in materials, energy efficiency, and price point. Vinyl is the least expensive, but laden with chemicals that off-gas inside the home, not to mention the footprint of creating virgin PVC. Wood is natural and lovely, but expensive, and requires the most maintenance. I ultimately chose a mid-range, aluminum-clad exterior, wood interior window with Energy-Star rated insulation. After quadruple-checking the measurements, I placed the 23-piece order and didn’t look back*. It was time to focus on the next phase — sourcing all the other materials that would make this construction site look more like a house.

*I actually did look back. A week after placing the “final-answer, can’t-be-changed, see-you-in-four-months” window order, I called the manufacturer in tears. I had a gut feeling the single window above the kitchen sink was too small. Thankfully, they hadn’t started manufacturing and were able to adjust the order. Decision fatigue was already setting in, but the process was just getting started.